Why Oxygen Generation is Essential to Onboard Medical Facilities

Having access to proper levels of oxygen is necessary for ships and crews of all sizes. In fact, both the IMDG (International Maritime Dangerous Goods) Code and MFAG (Medical First Aid Guide) dictate that ship operators carry 44 liters of medical oxygen at 200 bar. Many ships will carry 40-liter cylinders and two smaller 2-liter cylinders, which may not be enough in some cases.

Running out of oxygen while at sea can result in potentially fatal situations, making oxygen generation for ships a critical solution. With the continued threat of COVID-19, this problem has only intensified. If multiple crew members become ill with COVID-19 or require oxygen for another medical emergency, it is unlikely that the current mandatory oxygen levels will be enough. Situations may even develop where crew are not able to evacuate before oxygen levels run out.

Additionally, constantly refilling oxygen cylinders while at port is a logistical nightmare. There are multiple issues that can make switching out oxygen cylinders difficult. From the non-standardization of connectors to moving the massive oxygen cylinders off of the vessel, operators are looking for other methods to alleviate this burden. A potential solution for these issues is oxygen generation for ships.

How Does Oxygen Generation Work?

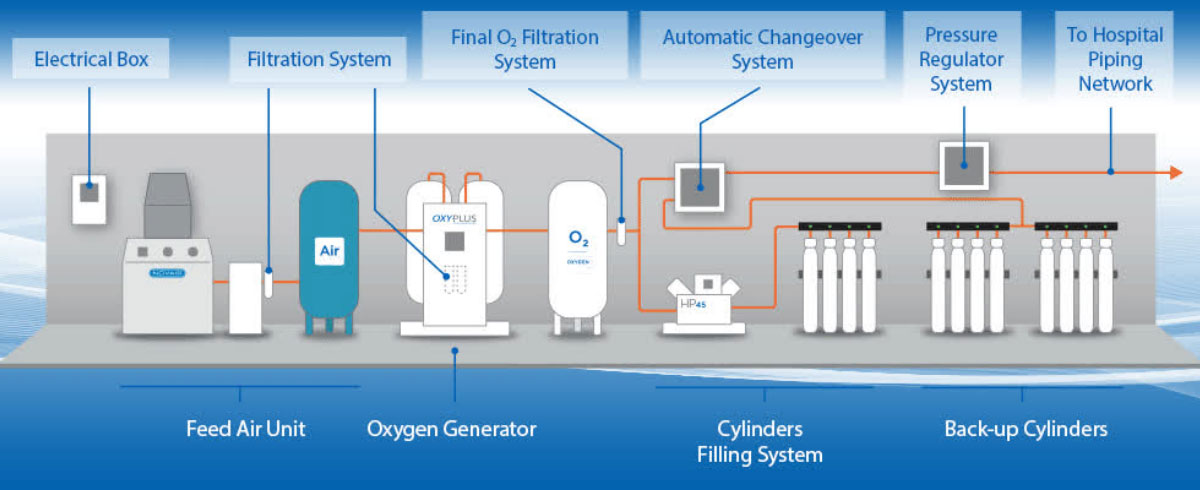

An oxygen generator separates oxygen from the air so that it can be used in a medical application. This is a relatively straightforward process that utilizes pressure swing absorption technology, and oxygen generators use a material called zeolite to filter out oxygen from the air.

An oxygen generator is typically composed of two towers. The oxygen generator goes through an absorption and desorption process that alternates in each tower. In the first stage of oxygen production, a stream of compressed air will flow through one of the towers and through the zeolite material.

Air is composed of 21% oxygen and 78% nitrogen, as well as other trace gases such as argon.

The oxygen molecules are small enough to pass through the zeolite material. The nitrogen molecules will be captured and absorbed by the zeolite material. This process will continue until the zeolite reaches full saturation and the material cannot absorb any more nitrogen molecules.

The nitrogen molecules are then released into the atmosphere. This occurs through a desorption phase. The cylinder containing the saturated zeolite will be rapidly depressurized, which will release the nitrogen to the environment. The absorption process can then begin again. The resulting gas will generally be between 90-95% oxygen. This process can be repeated several times until the oxygen levels reach purity levels of 99%.

Oxygen generators make operating a vessel a little bit easier.

The Benefits of Oxygen Generation

There are multiple benefits that oxygen generators can provide to ship operators.

- Medical staff will no longer have to worry about running out of oxygen in medical emergencies. All they will have to do is fire up the oxygen generator and refill the cylinders. Patients aboard container ships, cruise ships, and other vessels will have access to a nearly never ending supply of oxygen.

- Oxygen generators may sound like an expensive investment, but over time vessels can actually expect to save money. Organizations can save up to 80% of their oxygen costs by utilizing an oxygen generator, which can generally last 15 years. Once the initial investment is made operators can enjoy the benefits of generating their own oxygen.

- Crew members will also appreciate how much easier it is to fill up oxygen cylinders onboard. Because crew will no longer need to take cylinders off of the ship, logistics will be much simpler when crew members have to refill oxygen cylinders and can do so right onboard. Similarly, crew will not have to struggle to refill oxygen bottles while they are docked in port.

- Oxygen generators will save time. Since crew members only have to move a small, portable oxygen generator, they can spend their time focusing on other tasks instead.

- Provide a direct supply of oxygen for ventilated patients. Medical personnel do not need to wait for crew members to fill up an oxygen cylinder to administer oxygen to their patients. An oxygen generator can be used to deliver a steady supply of oxygen to patients in need without exhausting oxygen cylinder system supply.

- Designed to provide ample amounts of oxygen. Similar to a medical center on a ship with a small piping network, oxygen generators can provide oxygen to facilities for whatever their need is.

Overall, oxygen generators are a great investment for vessels of all sizes. Crew and medical personnel can rest easy at night knowing there is always an ample supply of oxygen ready whenever there is a need.

Are You Interested in Adding Oxygen Generation to Your Fleet?

Contact VIKAND today to learn more about our oxygen generation solutions. Our team is more than happy to develop a customized solution for your ship and answer any questions about how oxygen generation can benefit your organization.